Rock and concrete by nature have low tensile strength. By applying hydraulic force to a wedge, it is possible to tear off large sections of material from the inside in a matter of seconds.

Hydraulic Rock and Concrete Splitters allow controlled, silent and cost-effective operations!

Highly productive, they are the alternative conventional methods such as explosives and demolition hammers, since none of the related safety measures, costs and delays. The splitting cylinders are the solution especially in urban and sensitive areas and controlled demolition inside buildings, as there is almost no noise and vibration, as well as flying rocks. Demolition in residential complexes, offices, schools, hospitals during operation is therefore no problem.

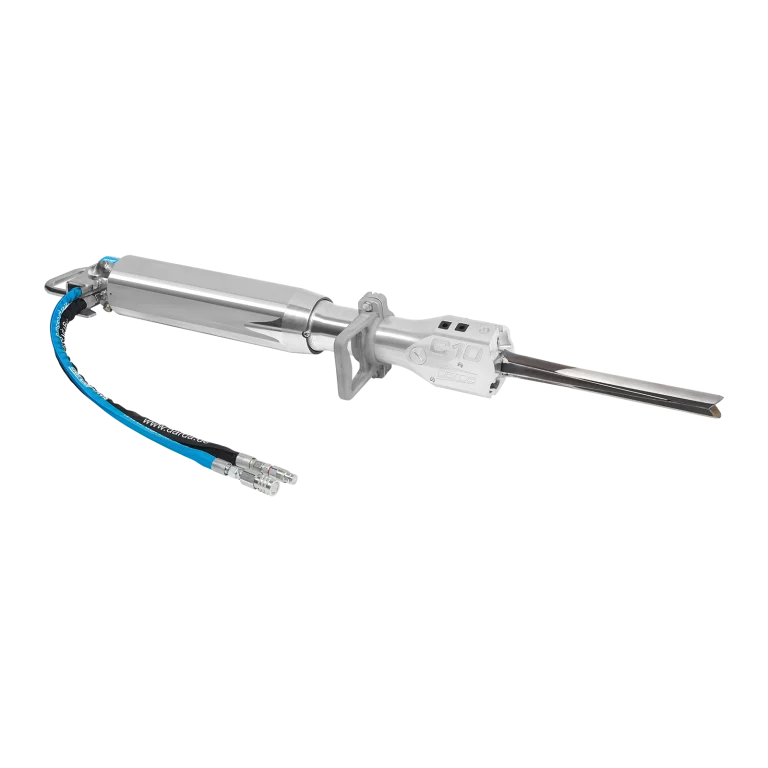

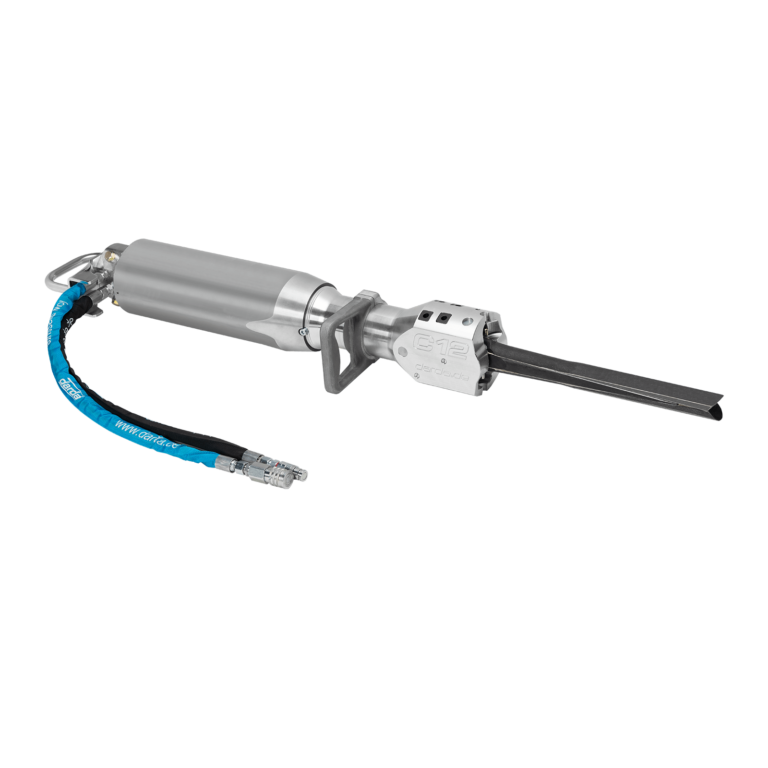

A splitting device is easy to operate and transport with only one man. The use in closed rooms in confined spaces or in poorly accessible places is therefore possible without any problems. The material is not pulverized by the splitting technique. The cohesion of the material remains given and the production of larger split pieces guarantee you with more volume per borehole highest productivity under safe conditions.

The handy Rock and Concrete Splitters have an enormous power-to-weight ratio. One person can work in any position and even under water, while other work continues in parallel: Silent, without vibrations and flying rocks.

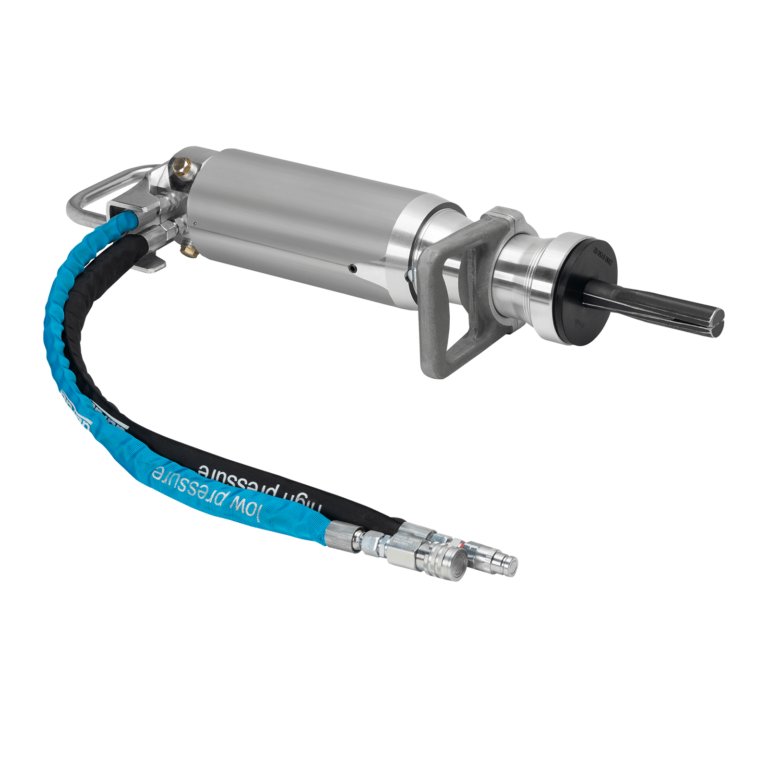

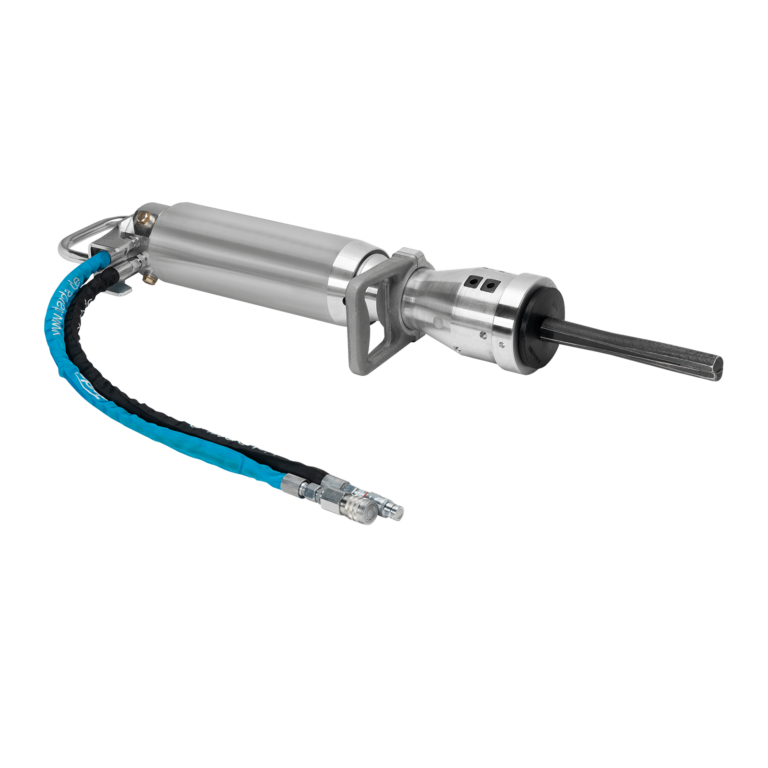

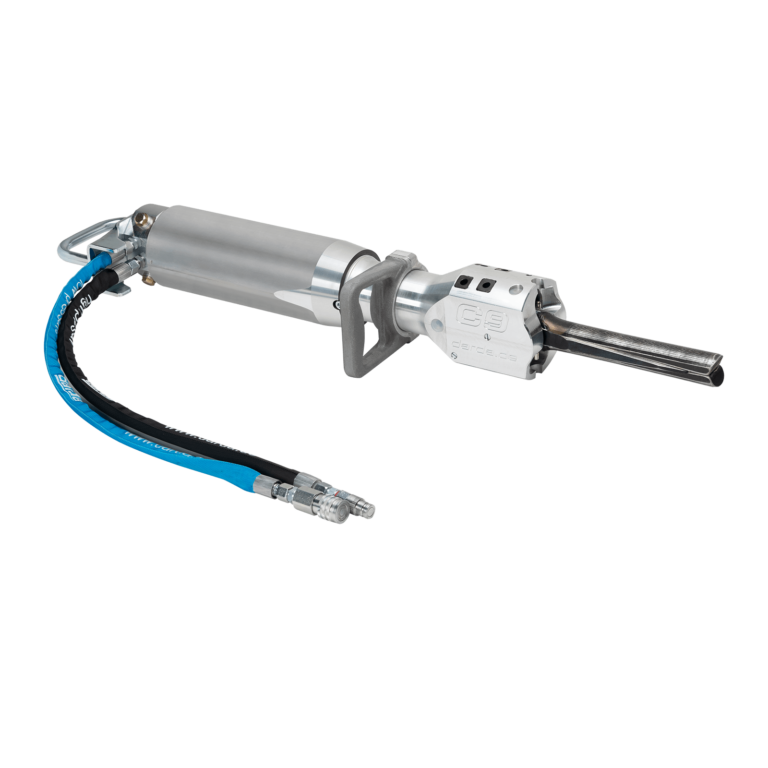

With five size models and different splitting inserts, matched to the prevalent material, we have the perfect solution for every operating condition.

Main areas of

application

Demolition of concrete

and reinforced concrete

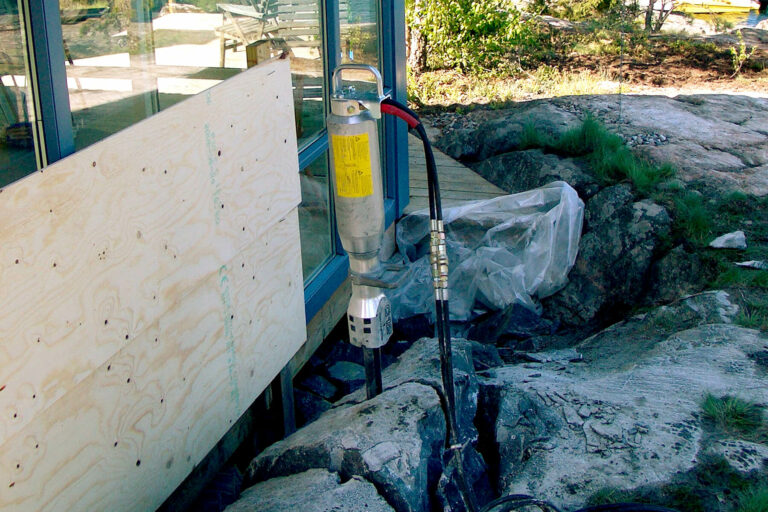

Lightweight and independent of carrier equipment, controlled demolition is guaranteed even in hard-to-reach places.

Demolition of rock

and natural stone

Efficient and gentle – the rock does not pulverize. The cohesion of the rock and thus larger split pieces/volumes per borehole are made possible.

Block quarrying in the

natural stone industry

Material that is not to be broken off is spared by precisely setting the direction of splitting and the course of splitting.

Tunneling

Time- and cost-intensive interruptions are eliminated. Splitting process proceeds while other work continues in parallel.

Conventional mechanical methods destroy the structure of the material by applying external force. Rock and concrete, however, can withstand very large compressive forces from the outside. In comparison, the resistance to a force acting from the inside out is relatively low. The development of the Darda Rock and Concrete Splitter was based on this fact.

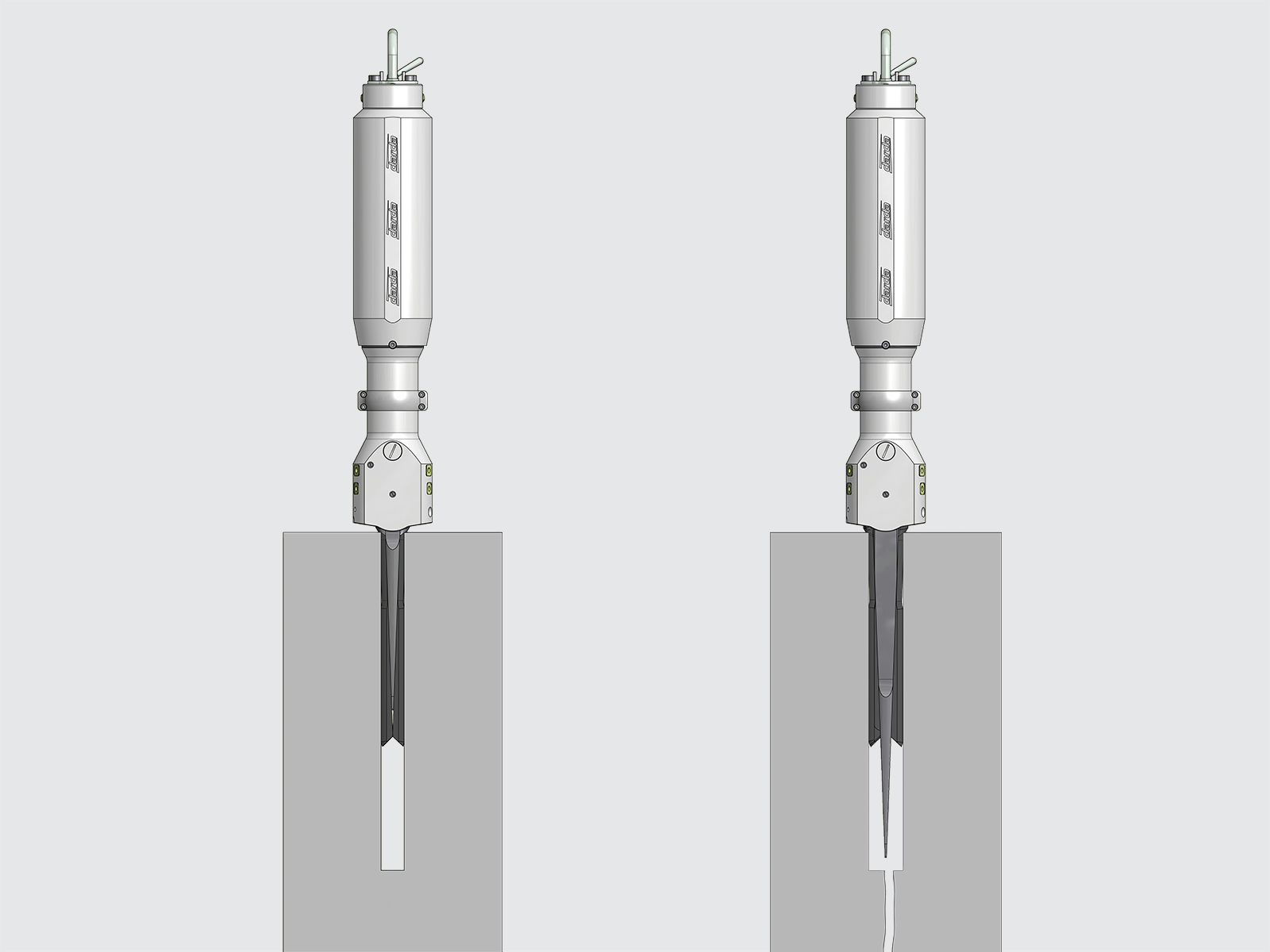

Safe wedge

principle

First, a hole of the appropriate depth and diameter is drilled, into which the splitting insert of the splitting cylinder is then inserted and aligned to determine the splitting direction. With hydraulic pressure, the wedge pushes itself between the two counter wedges and presses them apart. The effective splitting force of up to 413 tons or 4048 kN destroys the structure of concrete and rock from the inside. A split is created in a matter of seconds. Thinner reinforcing bars in reinforced concrete tear off.

C12 in Action

In this video, you will learn how the C12 hydraulic rock and concrete splitter works and what equipment is needed.

Darda – Rock and

Concrete Splitters

the original!

Invented and patented by the company founder Helmut Darda in 1967 – still market leading today. Produced at the headquarters in Blumberg, they proudly bear the “Made in Germany” label.

Darda Rock and

Concrete Splitters

make the

difference

Low vibration and dust almost noiseless

Powerful and usable everywhere

Robust and light

Economical and dimensionally accurate